Basket smart denester

Reliably unstack 35 baskets per minute.

Scroll for more information

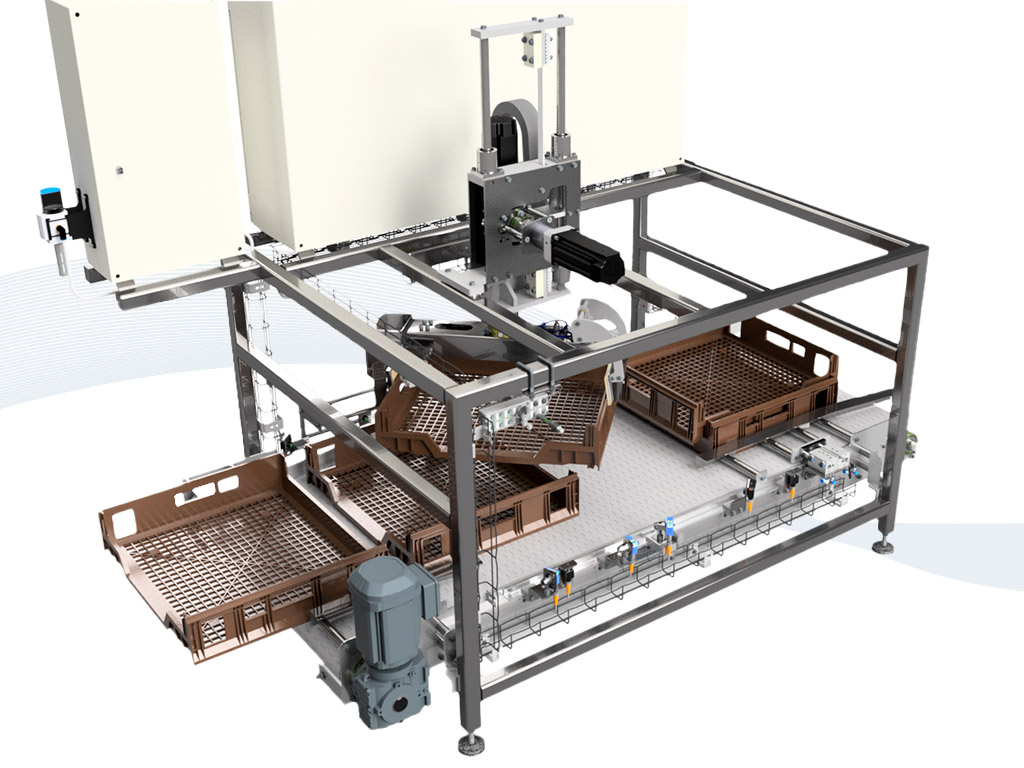

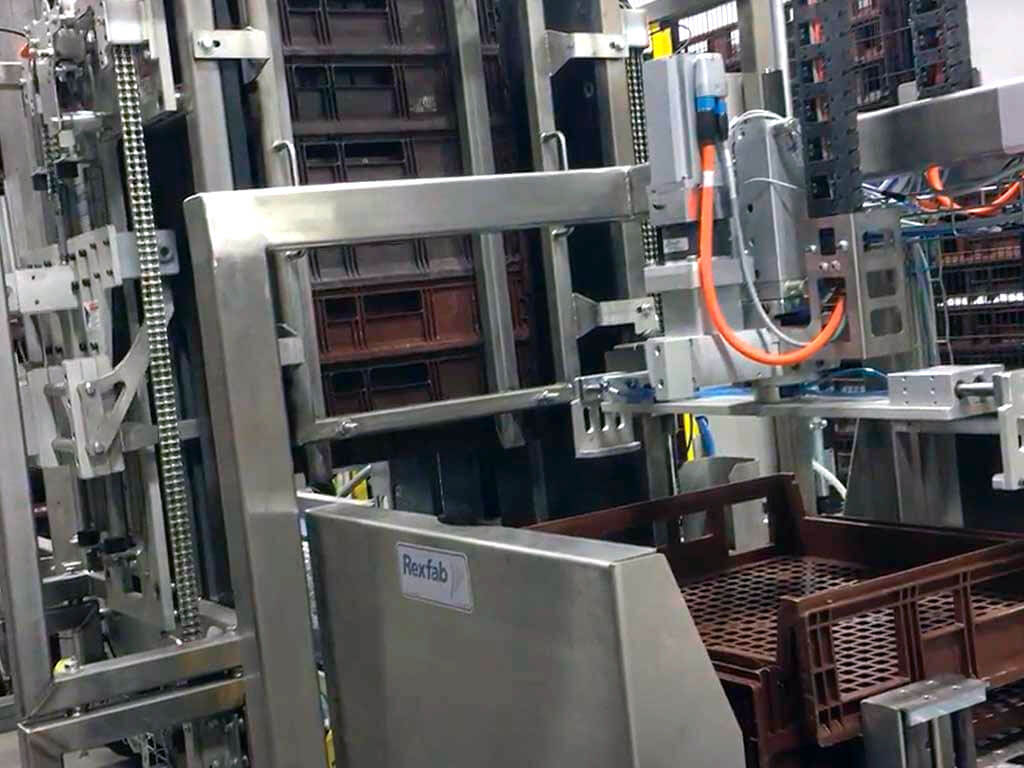

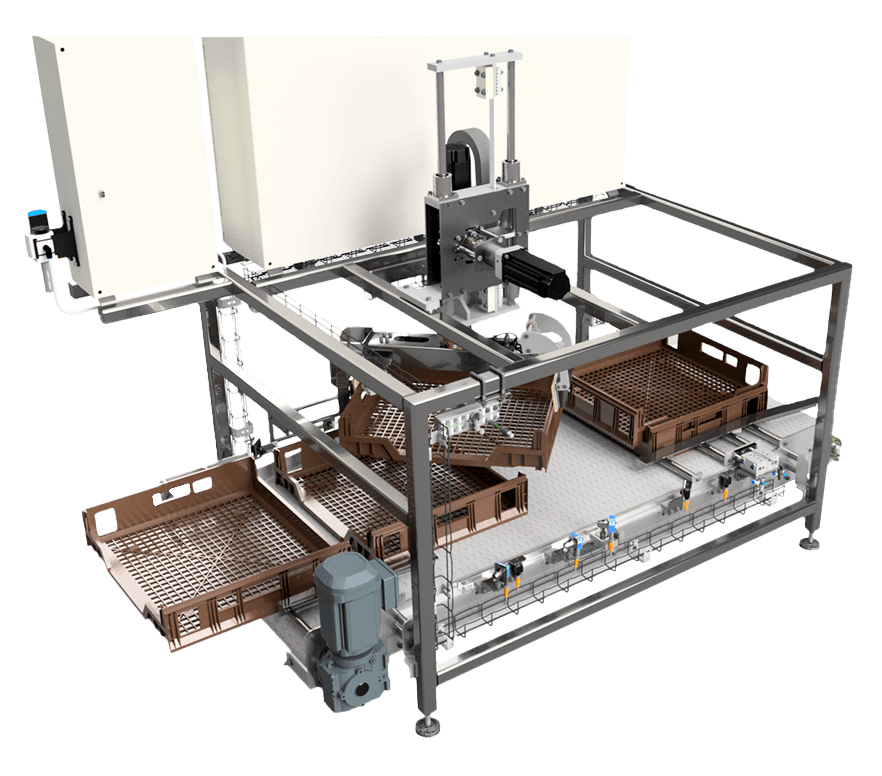

Rexfab’s Empty Basket Distribution System is designed to fit perfectly

within a bakery’s existing basket system to improve efficiency by eliminating labor.

The Empty Basket Distribution System’s Basket Unstacker

The unit’s denester reorients cross-nested baskets and provides window orientation using one arm driven by a servomotor. The Denester torque limiter protects the machine in unforeseen situations.

Automation starts with a conversation

basket smart denester features

- Intelligent basket detection.

- Adjustable denesting speeds.

- Compact footprint.

- Easy integration with loaders.

basket smart denester benefits

- Servomotor technology delivers reliability and precision with minimal maintenance.

- Continuous feed automation streamlines the downstream process and reduces labor requirements.

- Reduces basket damage.

- Design is identical to Basket Stacker, allowing bakeries to reduce spare parts.

- Designed to exceed safety and sanitation standards.

- Compact footprint saves space and is easily retrofitted into existing production line.

Ready to build the right solution for your production line?

Get in touch to start planning.